- Capsule Form Solution

- Tablet Form Solution

- Powder / Granular Form Solution

- Tablet Inspection Machine

- Powder Processing Solution

- Capsule Form Solution

- Tablet Form Solution

- Powder / Granular Form Solution

- Tablet Inspection Machine

- Powder Processing Solution

- Capsule Form Solution

- Tablet Form Solution

- Powder / Granular Form Solution

- Tablet Inspection Machine

- Powder Processing Solution

- Capsule Form Solution

- Tablet Form Solution

- Powder / Granular Form Solution

- Tablet Inspection Machine

- Powder Processing Solution

- Capsule Form Solution

- Tablet Form Solution

- Powder / Granular Form Solution

- Tablet Inspection Machine

- Powder Processing Solution

Soft Gel Encapsulation Machine

Automatic Soft Gel Encapsulation Machine Production Line for Omega3, Vitamins, Cosmetics, etc.

LTRJ-50 Lab Type Soft Gelatin Encapsulation MachineSend An Inquiry

LTRJ-50 Lab Type Soft Gelatin Encapsulation MachineSend An Inquiry LTRJ Soft Gelatin Encapsulation Machine Soft Gelatin Capsule Making MachineSend An Inquiry

LTRJ Soft Gelatin Encapsulation Machine Soft Gelatin Capsule Making MachineSend An InquiryGet More Information about Soft Capsule Filling Machine

Message *Please send us machine type, machine model, and production capacity etc.Name *Email *Phone *

Your Best Soft Capsule Filling Machine

from LTPM CHINA!

Softgel Encapsulation Machines: A Comprehensive Guide

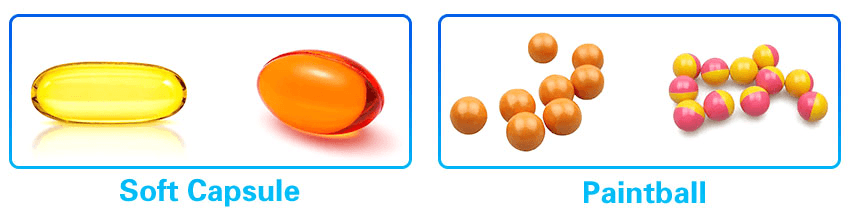

A softgel encapsulation machine is specialized equipment used in the pharmaceutical and nutraceutical industries to produce soft gelatin capsules. These capsules are popular due to their ease of swallowing, quick dissolution, and enhanced bioavailability compared to traditional tablets or hard capsules.

Key Components and Working Process

Softgel encapsulation machines consist of several crucial parts:

- Gelatin Melting Tank: Melts and maintains the gelatin at the correct temperature for forming the capsule shell.

- Spreader Box and Casting Drum: These create two gelatin ribbons, which are cooled and prepared for encapsulation.

- Injection Wedge: This device injects the liquid fill into the gelatin ribbons to form the capsules. The precision of this process is vital for accurate dosing.

- Die Roll System: The ribbons pass through a pair of die rolls that shape and seal the capsules. These die rolls can be customized to produce various capsule shapes (e.g., round, oval, oblong).

- Tumble Dryer: After encapsulation, the capsules are dried to remove excess moisture and harden the gelatin shell.

The process begins with melting the gelatin, forming the ribbons, injecting the fill, and shaping the capsules. Once formed, the capsules pass through drying systems to ensure stability before final packaging.

Gelatin Melting Tank

Spreader Box & Casting Drum

Injection Wedge

Die Roll System

Tumble Dryer

Benefits of Softgel Capsules

- Enhanced Bioavailability: Softgels dissolve quickly in the stomach, ensuring faster absorption of the active ingredients. This is particularly useful for oil-based or fat-soluble nutrients and medications.

- Customization: Softgels can be produced in various shapes, sizes, and colors, tailored to specific formulations and branding needs.

- Consumer Preference: Softgels are often preferred by consumers because they are easy to swallow and leave no unpleasant taste.

- Longer Shelf Life: Softgels protect sensitive ingredients from light and oxygen, extending their shelf life compared to other dosage forms.

Considerations for Choosing a Softgel Encapsulation Machine

- Production Scale: Machines range from small-scale models for R&D or small batches to large-scale units capable of producing hundreds of thousands of capsules per hour.

- Automation and Control: Modern machines feature programmable logic controllers (PLCs) and touchscreens for precise control over the encapsulation process, enhancing productivity and consistency.

- Material Compatibility: Ensure the machine can handle different shell materials, including animal-based gelatin and plant-based alternatives for vegetarian capsules.

For companies looking to enter the softgel market or improve their existing production capabilities, investing in a reliable softgel encapsulation machine is crucial. These machines offer both flexibility and efficiency, allowing for the mass production of high-quality, consumer-friendly products.

For more detailed specifications and options, you can explore the machines offered by LTPM China.

Service

1. 5 Year Warranty

2. Engineers available to service machinery overseas

Contact Us

Tel: +86-577-65158955

Mob: +86 13396976533

Email: info@

Service@

ltpmchina10@

© Copyright 2020 All rights reserved.