A pill tablet press is an essential piece of machinery in the pharmaceutical, nutraceutical, and cosmetic industries, designed to transform powdered substances into solid, uniform tablets. These machines are crucial for ensuring consistency in tablet production, allowing manufacturers to produce large quantities of tablets with precise dosages and uniform shapes. Understanding the mechanics, importance of pill pressure, and types of pill presses is vital for anyone involved in tablet manufacturing.

The Mechanics of a Pill Tablet Press

A pill tablet press operates through a series of well-coordinated steps, each of which is critical for producing high-quality tablets:

1. Material Preparation: Before the compression process begins, the powdered ingredients must be carefully prepared. This often involves blending the active pharmaceutical ingredients (APIs) with excipients such as binders, fillers, and lubricants. The goal is to create a homogenous mixture that will flow smoothly into the press and compress evenly.

2. Filling the Die: The prepared powder is fed into the machine’s hopper, which then transfers the material into the die cavity. The die cavity is a hollow space that determines the shape and size of the final tablet. The precision with which the die cavity is filled is crucial, as it affects the tablet’s weight and uniformity.

3. Pre-Compression: In this initial compression stage, light pressure is applied to the powder to remove any air trapped within the material. This step forms a loose compact known as a "slug," which helps to improve the uniformity and hardness of the final tablet.

4. 1Main Compression: The main compression stage involves applying a higher, controlled pressure to the slug. This force compacts the powder into a dense, solid tablet. The upper and lower punches of the press exert this pressure simultaneously, with the die cavity ensuring that the tablet retains its shape and size. The amount of pressure applied during this stage—referred to as pill pressure—is critical for ensuring that the tablets have the desired hardness, durability, and dissolution properties.

5. Ejection: After compression, the lower punch rises, pushing the newly formed tablet out of the die cavity. The tablet is then guided to a collection area, where it can be inspected for quality control. Modern pill presses often include mechanisms to detect and reject any tablets that do not meet specified standards, such as those with incorrect weight or inadequate hardness.

6. Quality Control: The tablets are subjected to rigorous quality control checks to ensure they meet all required specifications. This may involve testing for hardness, thickness, and weight, as well as conducting dissolution tests to ensure the tablets will release their active ingredients appropriately when ingested.

Pill Pressure: The Importance of Compression Force

Pill pressure refers to the force applied by the tablet press during the compression stage. This pressure must be carefully calibrated and controlled, as it directly influences the quality of the final product. The right amount of pressure is essential for producing tablets that are not too soft (which can cause them to break or crumble) and not too hard (which can make them difficult to dissolve or cause them to shatter during ejection).

Several factors influence the optimal pill pressure for a given tablet, including:

· Material Properties: The characteristics of the powder or granules being compressed, such as particle size, moisture content, and flowability, all affect how much pressure is needed to create a stable tablet.

· Tablet Size and Shape: Larger or more complex tablet shapes may require higher pressure to ensure the entire tablet is uniformly compacted.

· Desired Tablet Hardness: The intended use of the tablet, such as whether it needs to dissolve quickly or withstand handling during packaging and transport, also determines the required pill pressure.

Properly calibrated pill pressure ensures that the tablets are robust enough to withstand packaging and transportation while still being able to dissolve effectively in the body. Achieving the correct balance of these factors is crucial for producing high-quality tablets that meet both regulatory standards and consumer expectations.

Types of Pill Presses: Single-Punch vs. Rotary

Pill presses come in two main types: single-punch and rotary, each suited for different production needs and scales.

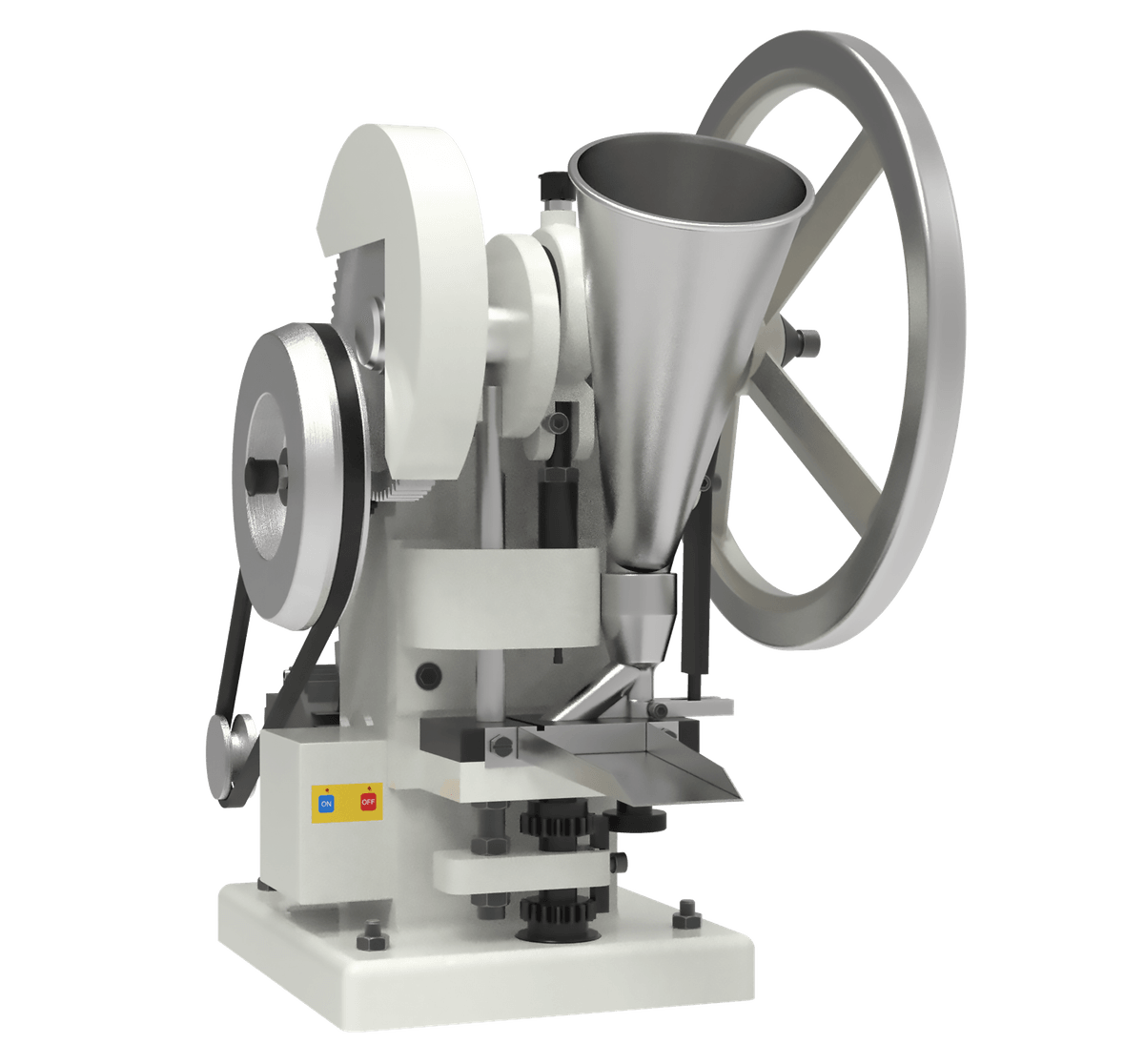

Single-Punch Tablet Press

A single-punch tablet press operates with a single die and a pair of punches (an upper and a lower punch). This type of press is typically used for small-scale production, such as in research and development labs or for producing custom batches of tablets. The simplicity of the single-punch press makes it easy to operate and maintain, which is why it is favored in environments where flexibility and ease of use are more important than production speed.

· Advantages: Single-punch presses are generally less expensive, easier to clean and maintain, and versatile in terms of the size and shape of tablets they can produce.

· Limitations: However, they are not suitable for large-scale production due to their slower production rates, as they can only produce one tablet per punch cycle.

Rotary Tablet Press

A rotary tablet press, on the other hand, is designed for high-volume production. It uses multiple punches and dies arranged on a rotating turret, allowing for continuous tablet production. As the turret rotates, each punch and die set passes through the filling, compression, and ejection stages, producing multiple tablets with each rotation.

· Advantages: Rotary presses can produce thousands of tablets per hour, making them ideal for large-scale pharmaceutical manufacturing. They are also capable of producing tablets of various shapes and sizes with high precision and consistency.

· Limitations: These machines are more complex, requiring more extensive maintenance and operator expertise. They are also more expensive, both in terms of initial investment and operational costs.

For manufacturers looking to scale up production while maintaining high quality, rotary presses are often the preferred choice. Companies like LTPM CHINA offer a range of rotary tablet presses designed to meet the demands of large-scale production environments. Visit LTPM CHINA to explore the options available.

Choosing the Right Pill Press for Your Needs

When selecting a pill press, it's important to consider your production scale, the types of tablets you need to produce, and the specific requirements of your operation. For small-scale or laboratory use, a single-punch press may be sufficient. However, for large-scale manufacturing, a rotary press is likely the better option due to its higher production capacity and greater efficiency.

Cost considerations are also important. While rotary presses offer higher output, they come with higher upfront costs and more complex maintenance requirements. It's crucial to balance these factors with the long-term benefits, such as improved production speed and consistency, which can lead to greater overall cost efficiency.

LTPM CHINA provides both single-punch and rotary tablet presses, tailored to various production needs. With advanced technology, robust construction, and comprehensive support, their machines are designed to deliver reliable performance and high-quality tablets. To find the right pill press for your operation, visit LTPM CHINA.

In summary, pill tablet presses are vital tools in the manufacturing of solid tablets. Understanding how they work, the importance of pill pressure, and the differences between single-punch and rotary presses can help you select the right equipment for your production needs, ensuring consistent quality and efficiency.