The manufacturing of tablets is a detailed process requiring precision to ensure that each pill contains the correct dosage and meets quality standards. Below is a breakdown of the key steps involved in tablet production:

1. Ingredient Preparation

The process begins with selecting the active pharmaceutical ingredient (API) and excipients. Excipients are inactive ingredients, such as fillers, binders, and lubricants, that ensure the tablet maintains its shape, improves stability, and aids dissolution. These ingredients are carefully weighed and blended to create a homogenous mixture, ensuring consistent dosage in every tablet.

2. Granulation (Wet or Dry)

Granulation transforms powders into granules, improving their flow and compression properties.

- Wet Granulation: The powders are mixed with a liquid binder to form a wet mass. This mass is then passed through a sieve to create granules, which are dried and screened for uniform size. Wet granulation is particularly useful for materials that do not compress well on their own.

- Dry Granulation: In this method, powders are compressed into large compact blocks and then milled into granules. Dry granulation is ideal for moisture-sensitive materials.

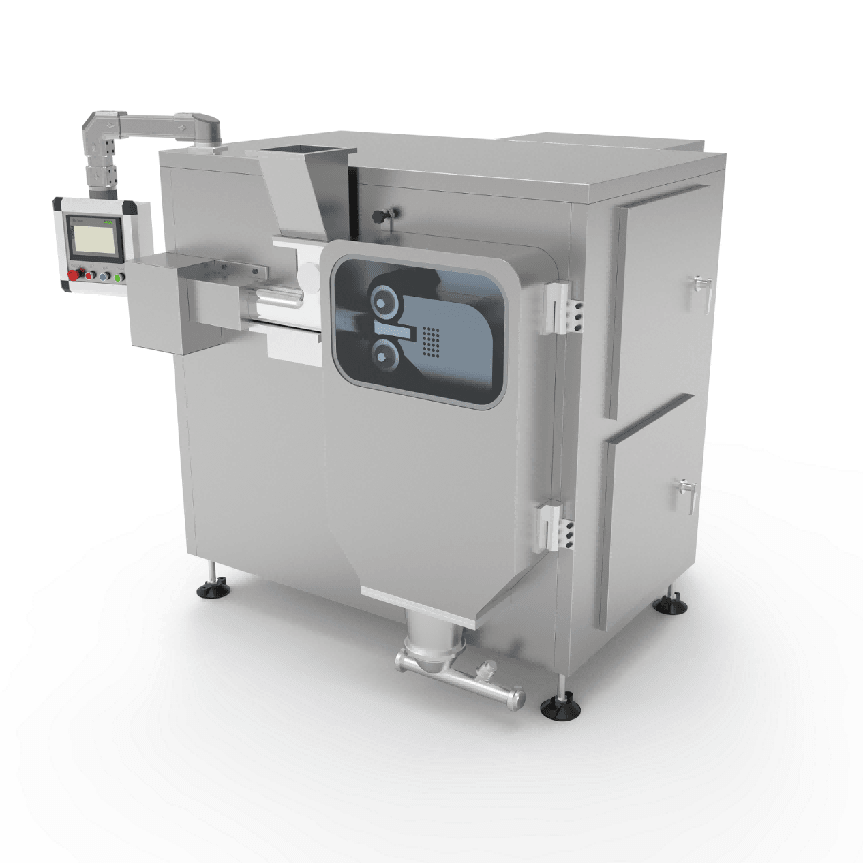

3. Compression

Once the granules or powder mixture is ready, it is fed into a tablet press. The press compresses the mixture into tablets by applying high pressure, ensuring the correct shape and size. The pressure must be optimized so that the tablet is neither too hard (which can delay disintegration) nor too soft (which may cause it to break easily).

4. Coating

After compression, tablets may be coated to improve their appearance, taste, and stability. Types of coating include:

· Film Coating: A thin polymer layer that protects the tablet.

· Sugar Coating: Enhances the taste and aesthetic appeal of the tablet.

· Enteric Coating: Prevents the tablet from dissolving in the stomach, ensuring it reaches the intestines for proper absorption.

5. Quality Control and Packaging

After manufacturing, tablets undergo rigorous quality checks for uniformity, weight, hardness, and dissolution. Once they pass these tests, the tablets are packaged in blister packs or bottles, ready for distribution.

The tablet manufacturing process involves precise control at every step, from ingredient selection to packaging. Each stage is essential in producing high-quality, effective tablets that are safe for consumer use. The use of advanced technology like rotary presses and coating machines ensures efficient, large-scale production with minimal defects. For more information on tablet production machinery, check out our product range at tablet form solution.