Enteric-coated tablets are a special type of pill designed to protect both the drug and your stomach. They have a unique coating that prevents the tablet from dissolving in the acidic environment of the stomach and allows it to dissolve in the intestines, where it’s safer and more effective. This guide will provide all the information you need to understand these tablets, including their benefits, how they work, and the manufacturing process.

- Introduction to Enteric-Coated Tablets

- How Enteric-Coated Tablets Work

- Benefits of Enteric-Coated Tablets

- Comparison: Enteric-Coated vs. Film-Coated Tablets

- Usage and Handling Guidelines

- Safety and Side Effects

- Frequently Asked Questions

- How Coating Machines Apply Enteric Coatings

What is an Enteric-Coated Tablet?

An enteric-coated tablet is similar to a regular pill but has a special coating that prevents it from dissolving in the stomach. It only begins to dissolve once it reaches the intestines. This means the active ingredient is released where it is most needed or can be absorbed without irritating your stomach lining.

This coating is particularly useful for medications that might irritate the stomach, such as certain pain relievers like aspirin or ibuprofen, or for drugs that do not perform well in acidic environments, such as acid-sensitive medications.

How Enteric-Coated Tablets Work

How Do Enteric-Coated Tablets Function?

Enteric-coated tablets use a special polymer coating that resists the acidic pH of the stomach. This coating only dissolves once it reaches the neutral pH environment of the intestines (about pH 6-7.4). This ensures that the drug inside is protected until it reaches the safe point for absorption.

Why Do Enteric-Coated Tablets Use Anionic Polymers?

Anionic polymers are a crucial part of enteric coatings. They remain intact in the acidic environment of the stomach (pH 1-3) but dissolve in the more neutral to alkaline environment of the intestines (pH 6-7.4). Here are some common anionic polymers used in enteric coatings:

- Methacrylic Acid Copolymers: They help the tablet dissolve at specific pH levels.

- Cellulose Acetate Phthalate (CAP): Provides protection against stomach acid.

- Hydroxypropyl Methylcellulose Phthalate (HPMCP): Used for higher pH-triggered release.

Benefits of Enteric-Coated Tablets

- Protect Your Stomach: They shield the stomach lining from potentially irritating drugs.

- Protect Sensitive Drugs: Some drugs need protection from stomach acid to remain effective.

- Targeted Drug Release: They release the drug where it will be most effective, leading to better absorption and efficacy.

Comparison: Enteric-Coated vs. Film-Coated Tablets

What is the Difference?

Film-coated tablets have a thin layer that dissolves in the stomach, mainly to enhance the product's appearance, taste, and ease of swallowing. Enteric-coated tablets, on the other hand, only dissolve when they reach the intestines.

Where Do Non-Enteric Film-Coated Tablets Dissolve?

Non-enteric film-coated tablets dissolve in the stomach. They do not protect the drug from acidic environments but can improve taste and swallowability.

Safety and Side Effects

Are Enteric-Coated Tablets Safe?

Enteric-coated tablets are generally safe when taken as prescribed. They are designed to minimize gastric irritation and enhance drug absorption. However, like all medications, they can have side effects depending on the active ingredient and individual reactions. Some people might still experience side effects depending on the drug and their tolerance.

Frequently Asked Questions

What Happens When You Crush an Enteric-Coated Tablet?

Crushing the tablet destroys the protective layer, leading to premature release of the active ingredient, which can cause stomach irritation and reduced effectiveness.

How to Tell if a Tablet is Enteric-Coated?

Enteric-coated tablets typically have a smooth surface and may be marked on the packaging. Be sure to check the packaging or consult your pharmacist to confirm.

Are Enteric-Coated Tablets Extended Release?

Not necessarily. Enteric-coated tablets delay release until they reach the intestines, while extended-release tablets are formulated to release the drug slowly over time, regardless of their location in the digestive tract.

How Coating Machines Apply Enteric Coatings

Tablet coating machines are crucial for the production of enteric-coated tablets. They ensure that the coating is applied uniformly, providing protection and proper release in the intestines. Here’s how the process works:

1. Preparation of Coating Solution

The coating solution is made by mixing polymers, plasticizers, and solvents to form a uniform solution that adheres well to the tablet's surface.

2. Loading of Tablets

Tablets are placed into the coating machine, which has a rotating drum to ensure each tablet is evenly exposed to the coating solution.

3. Application of Coating

- Spray System: The coating solution is sprayed onto the tablets through precise nozzles, ensuring even coverage.

- Controlled Environment: Temperature and humidity are closely monitored to ensure proper drying and prevent issues like clumping or uneven coating.

4. Drying and Curing

During coating, warm air circulates to dry the tablets. Proper drying is essential for forming a strong enteric layer that can resist stomach acid.

5. Quality Control

After coating, tablets are inspected to ensure the coating's uniformity and integrity. Any issues are corrected to maintain high pharmaceutical quality.

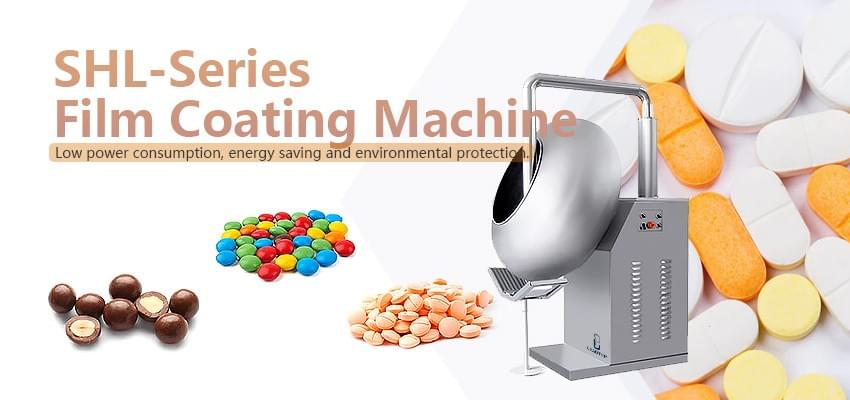

Introduction to Tablet Coating Machines

Producing high-quality enteric-coated tablets requires specialized machines. Here’s an overview of some advanced tablet coating machines:

1. BG Series High-Efficiency Intelligent Tablet Pill Film Coating Machine

- Application: Suitable for film and sugar coating of tablets, pills, and candies.

- Capacity: Models range from 10 kg to 350 kg per batch.

- Features:

- Integrated PLC control system with touch screen for precise control.

- High-efficiency spraying and drying system.

- Fast cleaning design for easy maintenance.

2. BYC Series Sugar Coating Machine

- Application: Ideal for sugar coating tablets and candies.

- Capacity: Suitable for small to medium batches, typically up to 70 kg.

- Features:

- Manual and automatic coating process options.

- Efficient drying system for rapid coating.

- Stainless steel construction for durability.

For more information on these machines and to request a quote, please visit our tablet coating machines page. These machines meet the highest industry standards, ensuring consistent quality and performance for your pharmaceutical manufacturing needs.