Capsule filling machines are crucial in the pharmaceutical industry, but they can fail, which can disrupt production and screw up product quality. You need to know where they fail and how to keep them from failing to keep things running and get the most out of them.

Yes, there are several critical points in the capsule filling process that can lead to mechanical failure. These include powder flow issues, misalignment, worn-out parts, environmental factors, and lack of operator training. To prevent these failures, you need to do regular maintenance, train your operators, do quality control, manage your environment, and have a way to fix things when they break.

1. Powder Flow Issues

You need good powder flow to get a good fill. If you have clumping, static, or bad flow properties, you won't be able to dose accurately, you'll jam the machine, or you'll damage your capsules. To prevent these issues, you need to choose powders that flow well, store your powders correctly, and clean and check your dosing system regularly.

2. Misalignment

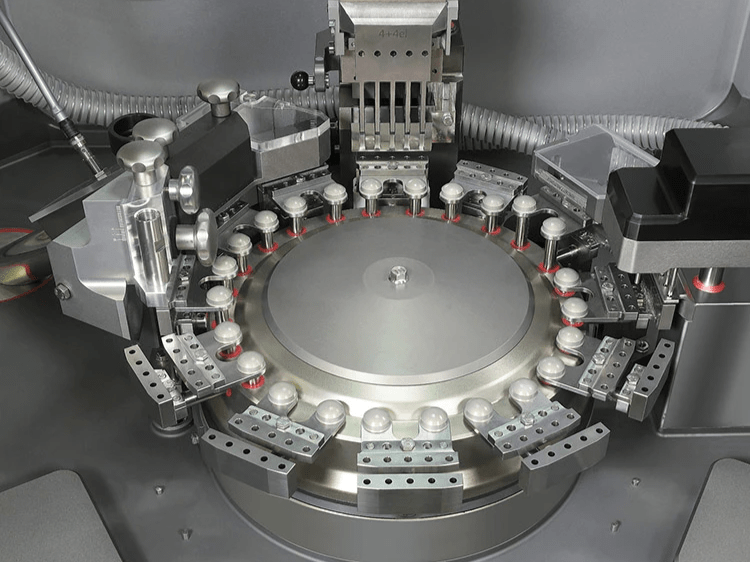

If your machine parts, like your dosing discs, capsule rings, or filling nozzles, aren't lined up right, you'll have uneven fills, your capsules will leak, and you'll put stress on your machine. You need to check and adjust your machine parts regularly to keep them lined up right, and you need to train your operators to spot and fix misalignment problems.

3. Worn-Out Parts

Parts that move a lot or rub together, like your sealing rubbers, tamping pins, or dosing discs, wear out over time. This can make your machine not work as well and can make it break. If you do regular maintenance, like lubing things and replacing worn parts, you'll make your machine last longer and you won't have as many surprise failures.

4. Environmental Factors

The conditions where you run your machine, like the temp, the humidity, and the air quality, can mess with how your machine works. If you keep your production area stable, like with temp and humidity control, you can keep your powder flow from changing and keep your machine from getting rusty or messed up.

5. Operator Training

You need to have people who know how to run your machine if you want it to run well and not break. You need to teach them how to set up and run your machine, how to take care of it, and how to fix it. You also need to teach them how to make sure your capsules are good and how to keep them safe. If you do this, you'll keep your machine from breaking and you'll keep it running good.

Why is routine maintenance crucial for preventing mechanical failures in capsule filling machines?

Regular maintenance helps identify and address potential issues before they escalate, ensuring consistent performance and prolonging the machine's lifespan. Scheduled inspections, lubrication, and part replacements are essential maintenance tasks to prevent mechanical failures.

How can operators ensure proper alignment of machine components to prevent mechanical failures during capsule filling operations?

Operators should undergo training on machine setup and adjustment procedures to ensure proper alignment of components. Regular inspections for signs of misalignment and prompt adjustments are necessary to prevent issues such as uneven filling or capsule damage.

What role do worn-out parts play in causing mechanical failures in capsule filling machines, and how can they be effectively managed and replaced?

Worn-out parts can compromise machine performance and increase the risk of breakdowns. Implementing a proactive maintenance schedule, including regular inspection and replacement of worn parts, helps to prevent mechanical failures and prolong the machine's lifespan.

In what ways do environmental factors impact the likelihood of mechanical failures in capsule filling machines, and what measures can be taken to mitigate these effects?

Environmental conditions such as temperature and humidity can affect machine performance and reliability. Maintaining stable environmental conditions within the production area helps minimize variations in powder flow and prevent corrosion or damage to machine components, reducing the likelihood of mechanical failures.

What training and skill development initiatives are necessary for operators to effectively prevent and deal with mechanical failures in capsule filling machines?

Operators should undergo comprehensive training covering machine operation, maintenance procedures, troubleshooting techniques, and safety protocols. Proper training empowers operators to identify and address issues promptly, minimizing downtime and ensuring efficient production operations.

In conclusion, understanding and addressing critical points of failure in capsule filling machines is essential for maintaining smooth operations and product quality in the pharmaceutical industry. By implementing preventive measures such as routine maintenance, operator training, quality control, environmental management, and troubleshooting protocols, manufacturers can optimize machine performance and minimize the risk of mechanical failures.

Ready to optimize your capsule filling operations? Contact us today for expert advice on machine selection, maintenance strategies, and training programs tailored to your needs. Plus, take advantage of our exclusive discounts on spare parts and accessories to ensure uninterrupted production. Don't let mechanical failures hold you back—let's keep your capsules flowing smoothly!